Norfolk Island Millstones

Quarried from Calcarenite Limestone

Topics: Limestone millstones, Calcarenite, querns, Norfolk Island First Settlement

Singleton Mills homepage > Overview of Stone types used for Millstones > Norfolk Island Millstones

A desperate need for flour on Norfolk Island

An outpost settlement was established by British colonists on Norfolk Island in 1788, just six weeks after the beginning of the colony at Sydney, New South Wales (NSW), Australia.

Above, the First Settlement on Norfolk Island in 1790. Painting by George Raper, Natural History Museum, London.

By 1792, the Norfolk Island population had grown rapidly to a peak of 1156, as more and more convicts were sent from Sydney to the island.

They needed to build large-scale flour mills to feed the settlement – but what millstones could they use to grind their flour?

The 'Publick Grindstone'

There were a few puzzling mentions of a 'Publick Grindstone' in the historic documents from the first five years of the First Settlement on Norfolk Island.

The Commandant, Lieutenant Philip Gidley King, noted in his journals:

– 'Carpenter making a Trough for the Grindstone' – 1788.[1]

– 'Convict Blacksmith making… Handle for mounting another Grindstone' – 1789.[2]

– 'For this Crime he was Chained to the Publick Grind Stone until an Opportunity may Offer of sending him to Port Jackson' – 1793.[3]

The term 'grindstone' is sometimes used for a stone that is used to grind grain.

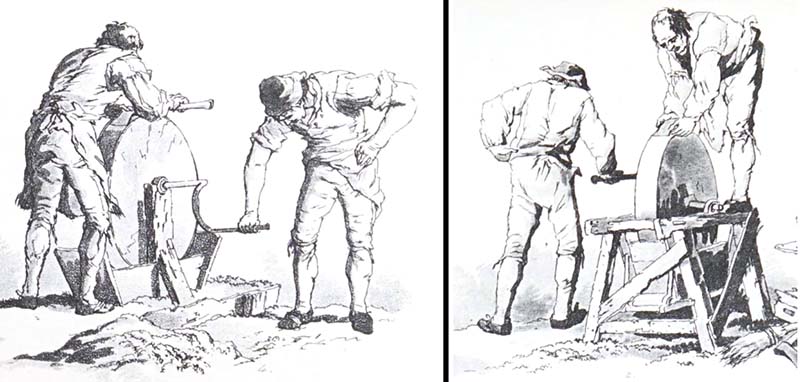

However, small details in the above records suggest that this grindstone on Norfolk Island was, instead, a large, hard, abrasive, disk of stone, used to sharpen steel tools, such as axes and knives (as shown below).

Tools could be sharpened on the edge of this type of grindstone, as another person rotated the stone using its crank handle, as shown below. The purpose of the trough may have been to keep the stone wet for certain sharpening operations.

Above, two sketches (1806) of men using grindstones to sharpen tools. From: 'Microcosm'; or 'A picturesque delineation of the arts, agriculture, and manufactures of Great Britain', by William Henry Pyne. archive.org

Having a grindstone of this type would have helped the Norfolk Island settlers keep their tools sharp. However, the colony still urgently needed a method of milling flour.

Stones to grind wheat or corn

Thirteen steel (or iron) hand-powered mills had been supplied to Norfolk Island for grinding grain, but these wore out quickly. Furthermore, weevils were destroying much of the settlement's precious supply of stored wheat, before it could be milled.

These problems could be solved if the settlers could manufacture milling stones from resources on the island.

Two different types of milling stones were possible:

1. Small stones (about 300 mm in diameter), that could be used in pairs to make a primitive hand-powered mill called a 'Quern';

or

2. Much larger and heavier millstones (more than 1 metre in diameter), that could be used in pairs to grind flour in a large-scale, powered mill.

Above left, a woman in India holds the handle of a pair of small quern stones used for grinding grain by hand. Above right, a man positions a full-sized millstone in a large-scale flour mill, whilst standing on the second millstone of the pair. Both images are from Wikimedia Commons: left, by Ramesh Lalwani; right, by Rasbak.

Attempts to make querns and millstones on Norfolk Island

Basalt was abundant on this volcanic island. The British colonists may have remembered that German, basalt-like millstones, called Cullin stones,A had been used to grind flour in England.

In 1790, King noted in his journal that an attempt had been made to cut querns from a local Norfolk Island stone (probably basalt). This was abandoned though, as the stone was found to be too hard.[4]

Then in 1791, another possible, softer, millstone material was found. The coastline along the southern shore of Norfolk Island, and down into the sea, was discovered to be made of a limestone called 'Calcarenite'. B

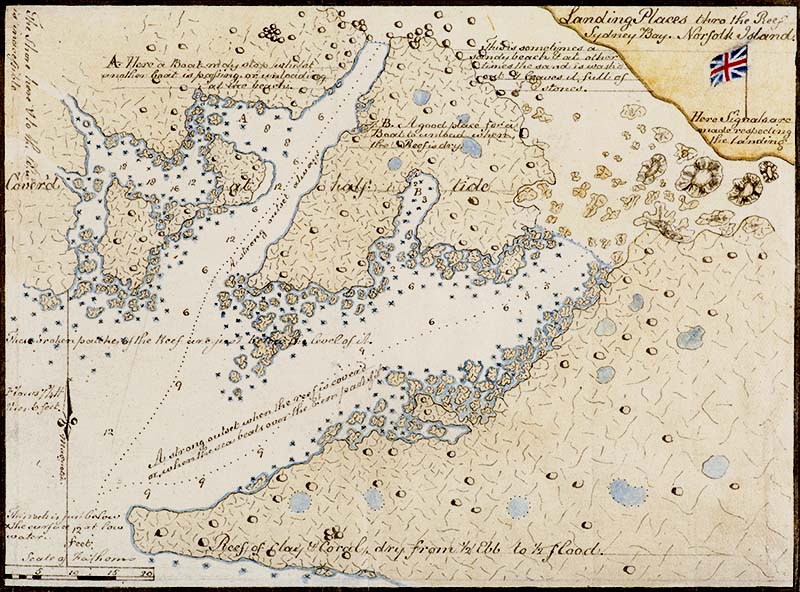

Above, a 1791 chart showing the limestone reefs, just offshore from the main settlement on Norfolk Island. The location of the settlement, with its flag and adjoining beach, is shown in the upper right hand corner. The extensive hatched areas on the remainder of the chart show limestone reefs that were fully or partially exposed during low or mid tide. While these reefs posed dangerous challenges to shipping, the calcarenite limestone in these reefs, and in adjacent shoreline boulders and outcrops, proved valuable for cutting querns and millstones. 'Landing places through the reef,' Norfolk Island, a chart drawn by William Bradley to help ships navigate the reefs near the First Settlement. State Library of NSW.

In March 1794, King reported an attempt to cut querns and millstones from some Calcarenite boulders that lay on the beach:

'The great distress which every Person Experienced for want of means to manufacture their Grain into Flour (As the hand mills are entirely useless) induced the only Stone Mason there is on the Island to make a Pair of Quearns from some Stones found on the Beach.

These answered so well, that I… employed the Stone Mason making a Pair of Mill Stones, Three Feet Six Inches Diameter, which is the largest Size the stones will admit of,

if we should be so fortunate to succeed and I find the Stones do not grit, this will prove a great Acquisition and be the only effectual Means of preventing the destruction occasioned by the Weevil.' [5]

A: Cullin stones. Also known as Cullen Stones, many millstones of a basalt-like stone, were imported from Germany into England during the 1700s.

B: Calcarenite Limestone. This is a rock composed of tiny grains (up to 2mm diameter) of calcium carbonate. The grains may include pieces of coral, shells, or ooids (rounded multilayered grains). These grains may have built up in a sand dune, beach, or shoal, before solidifying into a rock. Calcarenite Limestone is relatively soft – substantially softer than other stone types used for milling, such as sandstone, basalt, and chert.

The Calcarenite querns and millstones were both successful!

Numerous Calcarenite Limestone querns and millstones were put into use on Norfolk Island.

King ordered the production of many small querns from the Calcarenite, so that they could be distributed to the island households. King wrote in November 1794,

'The inconvenience attending the Labourer & others not being able to Grind their Ration of Grain is now done away, as there are very few who have not a Pair of Querns in their Houses, exclusive of those which are kept in a Mill-house for the Publick use.' [6]

The large Calcarenite millstones, too, worked well in the flour mills built during the First Settlement. King wrote to the Colonial Office in London,

'the Stones were as good as any that could be brought from England.' [7]

Norfolk Island millstones exported to NSW

As well as being successful on Norfolk Island, the Calcarenite millstones were so well regarded that a number were shipped to Sydney, NSW, in 1805, with millwright, Nathaniel Lucas:

'He brought also several pair of capital mill-stones, those of Norfolk being allowed superior in point of durability to any that can be procured here.' [8]

Norfolk Island had no harbour and was fringed with dangerous reefs. It was very difficult at that time to load heavy cargo from the island onto a sailing ship, and each millstone would have weighed at least one tonne. So, these Norfolk Island millstones must indeed have been seen as 'superior', to justify transporting them to Sydney.

Calcarenite Limestone Millstones

|

Why were the Norfolk Island millstones seen as 'superior'?

Limestone had been used historically to cut querns in Europe and England. However, harder stone types such as chert, basalt, and Millstone Grit had been preferred for millstone production for hundreds of years.

So, the newspaper comment (quoted above) that the Norfolk Island millstones were considered better than those available in Sydney is of great interest.

It can be explained as follows:

1. The British colony of Sydney, NSW, was built in the 44,000 km2 Sydney Basin, an area that is predominantly sandstone.

2. In Britain and Europe, hard varieties of sandstone, especially those where the sand grains are firmly bound with a hard high-silica cement, had been successfully used for millstones. (For example, British millstones made from Millstone Grit or Puddingstone.)

3. However, the sand grains in Sydney's sandstone are mainly bound with a soft clay cement. A millstone made from Sydney's sandstone would deposit unacceptable amounts of gritty sand into the ground flour.

4. In contrast, by 1805 the Calcarenite limestone millstones of Norfolk Island had been successfully used for milling flour in that settlement for 11 years (1794 until 1805). The grains in this type of limestone are soft particles of calcium carbonate, that would leave little gritty residue when used to mill flour.

Above, some Calcarenite Limestone from an outcrop on Point Hunter, Norfolk Island. The full width of this image shows a 20mm-wide section of the stone. Macro image by Anne Dollin.

Read more about the best stone types for making millstones

A 2023 study of a surviving Calcarenite millstone on Norfolk Island

In an archaeological study of Norfolk Island in 2023, a Calcarenite Limestone millstone was identified and examined.[9] It may be the only surviving millstone that can be seen now on the island.

This millstone had originally been found in a foreshore Calcarenite quarry site, near today's township of Kingston, Norfolk Island. The stone had been exposed to the surf for many years and was badly eroded. So, it had been later moved to a protected site on a building veranda.

The diameter of this millstone was about 1350 mm, and it was 300 mm thick. From its large size, it would appear to have been intended for use in a powered flour mill (i.e., a watermill or a windmill). A rounded piece of dark igneous rock (possibly basalt) was embedded in the grinding surface of the stone.

This archaeological report[9] is of great interest as it describes one of the few examples that remain of the numerous Calcarenite millstones that were quarried on Norfolk Island.

The significance of the Norfolk Island millstones

The British settlements of Norfolk Island and Sydney had been extremely isolated during their first decades. This had made it very difficult, or even impossible, for millers to import millstones for their mills.

So, the mill builders on Norfolk Island would have benefitted greatly from the abundant supply of Calcarenite Limestone millstones that could be quarried on the island.

For the millers in Sydney, NSW, too, in those early decades, Norfolk Island millstones would have been a welcome option for their mills, until supplies of more preferred millstones, such as French Burr Stones, became available.

REFERENCES

1. Fidlon, PG and Ryan, RJ (1980) The Journal of Philip Gidley King: Lieutenant, R.N. 1787–1790. Australian Documents Library, Sydney, page 101.

2. Ibid, page 141.

3. Journal of Philip Gidley King while Lieutenant-Governor of Norfolk Island and Letter to Mrs Gov. King, 1791-1796, Trove: https://nla.gov.au/nla.obj-26005434/view?partld=nla.obj-26038525, Image 92.

4. Fidlon, PG and Ryan, RJ (1980) The Journal of Philip Gidley King: Lieutenant, R.N. 1787–1790. Australian Documents Library, Sydney, page 188.

5. Journal of Philip Gidley King while Lieutenant-Governor of Norfolk Island and Letter to Mrs Gov. King, 1791-1796, Trove: https://nla.gov.au/nla.obj-26005434/view?partld=nla.obj-26038525, Image 146.

6. Colonial Office Records 1774-1951, 201.10, page 264. https://nla.gov.au/nla.obj-914011294/view

7. Ibid.

8. The Sydney Gazette and New South Wales Advertiser, 17 March 1805.

9. Jackson, G and Forbes, P (ca. 2024) A mill stone on Norfolk Island. https://www.academia.edu/110253405/A_Mill_Stone_on_Norfolk_Island

Read More About Millstones

•• Overview •• French Burr Stones •• Basalt-like Cullin Stones •• Millstone Grit •• Old Red Sandstone, Puddingstone, and Lodswoth Stone •• Granite •• Limestone •• Artificial Millstones •• Colonial Millstones ••

Read More About Norfolk Island's Flour Mills

•• Overview •• First Settlement Flour Mills •• Second Settlement Flour Mills •• Nathaniel Lucas •• Robert Nash ••