Millstone Types: Artificial Composition Millstones

With granulated Burrstone, emery, or slag

AKA Composite stones*

* Note: the term 'Composite stone' usually refers to millstones which are constructed from multiple large wedges of stone, fitted together into a millstone shape, such as the later French Burr Stones. However, 'Composite stones' is also an alternative name for Artificial Millstones.

Singleton Mills homepage > Overview of Stone types used for Millstones > Artificial Composition Millstones

Making Artificial Millstones

Artificial Composition Millstones were manufactured from grains of abrasive material cemented into a millstone shape, inside a mould. The materials included granulated French Burr Stone, granulated rock emery, or slag. Artificial stones made from French Burr were used for grind grain for humans, while animal feed was produced with the other two types of stone.[1]

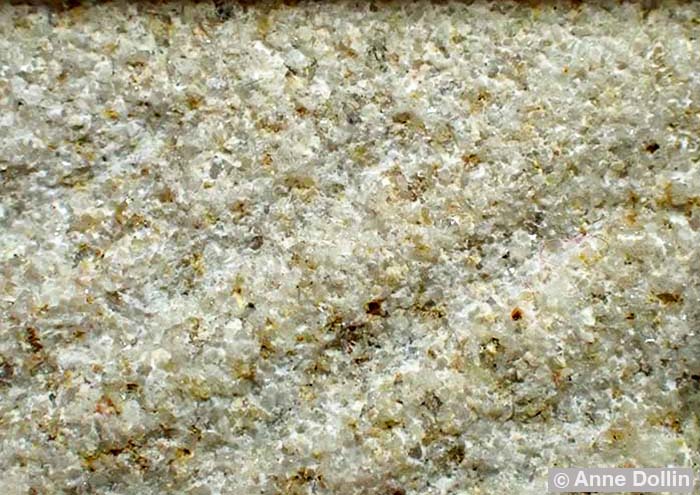

Above, detail of an artificial composition (or composite) millstone, made up of granulated chips of French Burr Stone set in a special cement. The full width of this image shows a 20mm-wide section of the stone. Macro image by Anne Dollin.

Iron bands were fitted around the edges of Artificial Millstones so that they did not shatter when rotated at high speeds. Due to the durability of the materials, their surfaces did not need to be re-dressedA as often as those made from natural stone millstones did.[1]

Above, a composition millstone made from artificial stone in the Netherlands. Photograph by Rasbak. Wikimedia Commons.

In Gloucester, UK, the WS Barron & Son mill engineering works produced, at its height, about 1000 artificial millstones per year. To make their 'Dreadnought' composition stones, they ground French Burr stone, carborundum, or emery down to a particle size of 3mm or less. This material was embedded in a strong cement, then cast into a circular millstone mould of the desired millstone size. Millstones of up to 1.5m in diameter were manufactured. Their millstones were given a heavy cast iron back plate to provide mechanical strength. [2, 3]

Glass millstones!

In Germany, artificial millstones for grinding wheat were even constructed from solid glass! Blocks of glass, about 15 to 30 cm wide, were cast in wedges (similar in shape to the blocks of solid French Burr Stone that were used to construct millstones). The blocks were glued together with cement and the completed stone was dressed,A as usual, with iron tools. These glass stones were said to be as durable as French Burr Stone and, unlike other stone types, they remained cold while grinding the wheat.[1]

A: Dressing Millstones. Intricate dressing patterns were chipped into the surfaces of millstones used in flour mills to help with the grinding process.

References

1. Hockensmith, Charles D (2009) The Millstone Industry. McFarland & Company, Inc, Publishers, pages 199-201.

2. Mills, Stephen (2007) W.S. Barron & Son, Mill Engineers of Gloucester. Gloucestershire Society for Industrial Archaeology, Journal for 2007, pages 45-49.

3. Mills, Stephen (2023) What are 'composition' millstones? Gloucestershire Society for Industrial Archaeology, Article June 2023.

Read More About Millstones

•• Overview •• French Burr Stones •• Basalt-like Cullin Stones •• Millstone Grit •• Old Red Sandstone, Puddingstone, and Lodswoth Stone •• Granite •• Limestone •• Norfolk Island Millstones •• Colonial Millstones ••