Flour Mills of the Second Norfolk Island Settlement:

1825 to 1855

Topics: Second Settlement flour mills, watermill, crankmill, treadmill, post-mill, horizontal windmill, millstones

Singleton Mills homepage > Norfolk Island Flour Milling Overview > Flour mills of the Second Settlement of Norfolk Island

Establishment of the Second Settlement

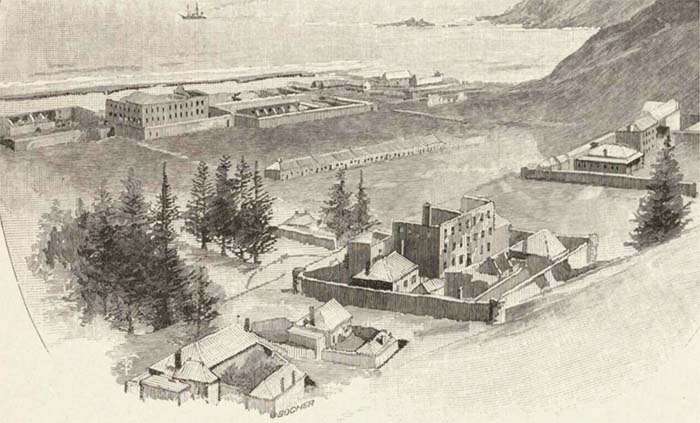

The Second British Settlement on Norfolk Island was established in 1825 as a penal colony for Britain's worst convicts. It ran for about 30 years and housed up to 700 convicts at one stage. Substantial mills were needed to provide this population with rations of wheaten flour and corn meal.

Above, a drawing of Kingston, the Second Settlement on Norfolk Island, in about the 1840s. From the Picturesque Atlas of Australasia, Volume 3, page 698, 1886.

Flour mills of the Second Norfolk Island Settlement:

– A rebuilt watermill

– Steel hand-mills

– The convict-powered crankmill

– A rare horizontal windmill

– Other windmills

The rebuilt watermill at Arthurs Vale

A watermill, a dam and water races had been constructed in Arthur's Vale, Norfolk Island, during the First Settlement period. The mill was powered by water diverted from Watermill Creek, which flowed through this valley.

All the First Settlement buildings, including the watermill, had been destroyed when the settlement was closed in 1814, to deter others from claiming the island. However, the mill dam and the water races of the watermill, which had been dug into the ground, survived.

In 1828, work began to construct a Second Settlement flour water mill in Arthurs Vale. It used the dam and mill races dug for the First Settlement mill, but the mill building itself had to be completely rebuilt.[1]

The mill was designed with an overshot waterwheel on the north-eastern end of the building. However, it operated as an undershot mill. It had an underground vaulted head race and a shallow tail race. The grinding machinery used in the watermill included some equipment for a treadmill, that had been shipped to the island – the other treadmill components had "accidentally" fallen into the sea whilst being unloaded.[2]

Unfortunately, within a few years, serious problems developed with the watermill. The mill machinery needed repairs, and by 1833, persistent seepage from the mill dam meant that it could not hold enough water to keep the mill operating.

In 1837, 100 convicts worked for a month repairing the mill machinery and the dam. Even after this, the Royal Engineer, Lieutenant Henry Lugard, complained that,

'nearly as much water filters through the sides and flooring as is supplied by the natural streams so that it is only in rainy weather that the mill may be termed effective.' [3]

Further remedial work was proposed. However, a convict-driven crankmill was planned for the settlement, which would soon reduce the need for the watermill.

Remains of the Second Settlement watermill, which fell into ruins by the 1890s, can still be seen in Arthurs Vale today.

Above, the ruin of the Second Settlement watermill that had been built in Arthur's Vale (now called Watermill Valley), Norfolk Island. The front part of this building was the mill itself, with the waterwheel originally mounted on the now-missing wall in the foreground. In the back part of the building were two rooms that were the miller's living quarters. A small weatherboard kitchen was erected adjacent to the rear wall of the mill building. Photograph by Tony Hugo.

Iron hand-mills

In the 1830s, the Second Settlement on Norfolk Island was supplied with 26 steel (or iron) hand-mills for grinding grain, due to the many problems that were being experienced with the watermill. More details about iron hand mills. These hand-mills were installed in the upper floor of the Beach Store building (see photograph on left, below). Half of the mills were for cracking corn and the other half were for grinding the cracked corn into meal. Disabled or exempt prisoners were assigned to this work, and two men worked each mill.[4]

As in the First Settlement, these hand-mills soon wore out from being constantly in use. However, Thomas Bunbury, Commandant of Norfolk Island in 1839, also claimed that the convicts sabotaged these mills. He wrote in 1861,

'The iron hand-mills for grinding corn cost Government a great outlay every year, as the prisoners found it to their interest to spoil them, in order that the corn might be sent to Sydney to be ground.' [5]

The convict-powered Crankmill

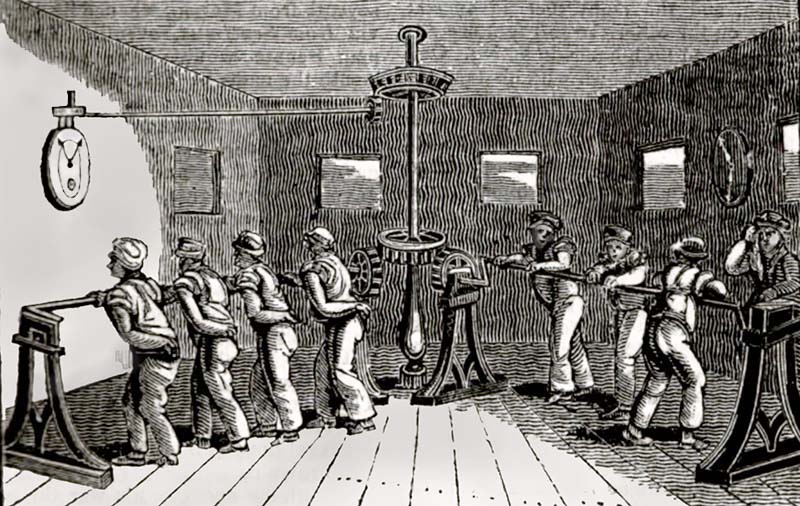

Then in the late 1830s, a crankmill, powered by 48 convicts at a time, was set up to mill grain for the settlement. This aligned with the key purpose of the Second Settlement, which was for harsh penal punishment. An even more-gruelling treadmill design was also proposed, but this was never constructed.

Above, the ruin of the Crankmill building on Norfolk Island: left, the Crankmill building ruin (lacking its roof) is seen here behind the Beach Store building (also known as the Pier Store); right, an interior view of the Crank mill building ruin. The left photograph, dated 1983, is from the National Archives of Australia; right photograph by Mark Harvey.

A crankmill is basically a set of gears turned by a handle. In the case of this Norfolk Island crankmill, two long iron handles were turned, with immense effort, by 48 convicts at a time. The handles rotated a large gear wheel, which was connected to the grinding millstones. The convict teams and the first gear wheel were located on the lower floor of the crankmill building, whilst the grinding equipment was on the upper floor.[6]

Above, this rare sketch shows how a crankmill system could be used to power a flour mill in a prison setting. Published in an 1823 magazine, this crankmill design was recommended by Sir John Cox Hippisley as being safer and more effective than a prison treadmill. The Norfolk Island Crankmill used two long crank handles, as shown in this sketch. However, they would have been much longer, as 48 men operated the Norfolk Island Crankmill at a time. The Mirror of Literature, Amusement, and Instruction, Volume II, No. XLVII, 13 September 1823. babel.hathitrust.org

The crankmill was frequently out of service because the convicts discovered techniques for breaking the gears. Bunbury wrote,

'The crank-mill… took double the necessary number of men to work it. By sudden jerks on one particular part, whilst at other points no mechanical effort was used, they would strain the machinery and soon render it unserviceable.' [7]

In the 1840s, windmills were constructed on the island. These then provided most of the meal needed by the population, largely replacing the crankmill.

Horizontal Windmill at The Cascade

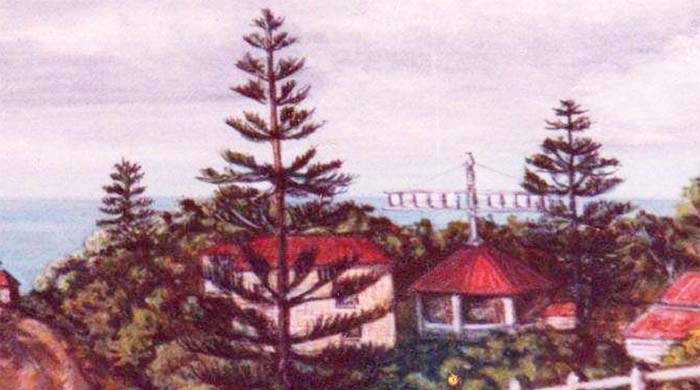

An intriguing horizontal windmill was built, in about the 1840s, at The Cascade settlement in the northern part of Norfolk Island.[8, 9]

This mill's location was marked, as a ruin, on a survey plan drawn by Sapper George Jamieson, RE, in 1858 (see below). The mill's ruins were also shown on an archaeological survey map drawn by RVJ Varman in 1984.[9]

Above, detail of an 1858 survey plan by Sapper George Jamieson showing the outline of the horizontal windmill building at The Cascade, along with some measurements of its size. The building is labelled as 'Old Mill in Ruins'. Norfolk Island Book. No. 1. Surveys by Sapper George Jamieson, R E, July - November 1858, page 20. National Archives of Australia.

A painting held by the Norfolk Island Research Collection suggests that this windmill had an extremely rare design. Two (or possibly four) wind vanes turned horizontally on top of an hexagonal building to power the mill. The wind vanes were, unusually, covered with old ship sails. The walls of the horizontal mill building were made of basalt, and a large timber post may have originally stood on each corner.[9]

Above, Norfolk Island's rare horizontal windmill is shown in this painting of The Cascade settlement. The vanes of the windmill, supported by wires, are mounted on the roof of this low building. Painting in the Norfolk Island Research Collection, as shown in Duncan et. al. (2014) [9]

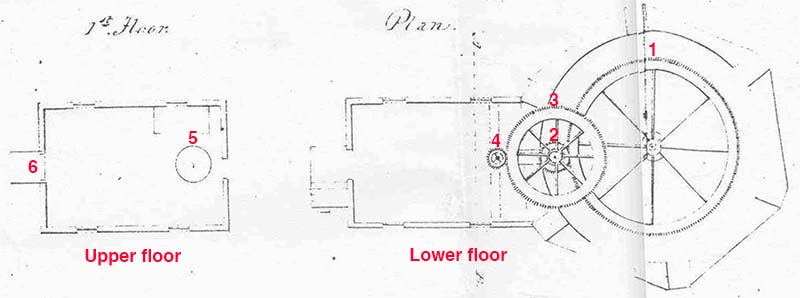

The internal design of the mill, including its gear wheels, and the design of the adjoining two storey building, are also shown on a plan held by the Norfolk Island Research Collection:

Above, this undated plan shows the horizontal windmill and the adjoining two storey building that housed the milling equipment. For an explanation of the numbered gear wheels that we have marked on this plan, see the blue box below. Adapted from a plan drawing in the Norfolk Island Research Collection, as shown in Duncan et. al. (2014) [9]

HOW DID NORFOLK ISLAND'S HORIZONTAL MILL WORK? Commentary by Les Dollin: Based on both the painting and the plan of the Horizontal Mill, shown above, the way that this mill worked was probably as follows: The wind vanes were elevated high on a shaft above the hexagonal building, to catch the wind. Each wind vane would have been fitted with six individual panels or blades. The angle of each blade could have been adjusted to suit the strength of the wind. A large vertical shaft ran from the wind vanes down into the hexagonal building. Inside the hexagonal building: The interconnected gear wheels (1 – 4) would have greatly increased the rotational speed produced by the wind vanes. That is, gear wheel (4) would have been spinning massively faster than the wind vanes and gear wheel (1). This greatly increased rotational speed was crucial. Millstones must spin very quickly in order to properly grind grain, and throw the milled flour towards the outside edges of the millstones by centrifugal force. This system would have been strong enough to run a small set of millstones (such as 0.9m diameter), especially if they were grinding a soft grain such as corn. |

Other Windmills

An effective windmill, using a post-mill design, was also built in 1842-1844 on Point Hunter during the Second Settlement. This location is close to where a windmill was built during the First Settlement.

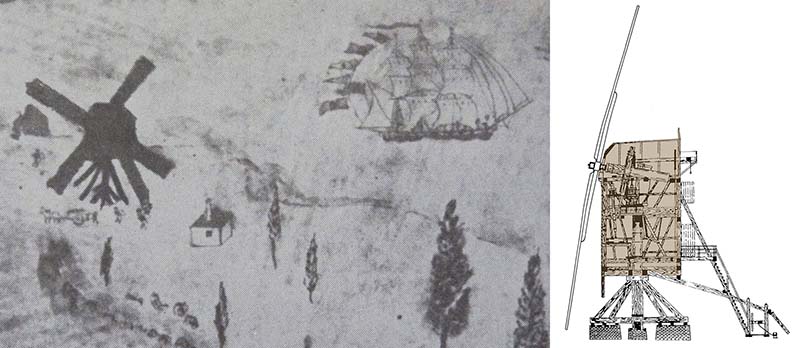

Above, detail from a drawing of the Second Settlement in about 1845-1846, showing the postmill on Point Hunter, together with a cross-sectional diagram of a postmill showing its main features.

– The diagram (right) shows that a postmill consists of a wooden building bearing the windmill vanes, supported on a pyramid of wooden posts. A long pole, used to rotate the whole mill building into the direction of the wind, extends towards the ground on the far right.

– The sketch of the postmill on Point Hunter (left) shows its four wind vanes, and its extended pole for turning the building (on lower right of mill). The pyramid of supporting posts under the mill is also shown. The miller's hut is shown on the right of the mill, and a tiny sketch of a horse and cart, with several workmen, has even been included – along with a beautiful sketch of a sailing ship bedecked with flags.

Left, detail from drawing entitled 'View of Settlement at Norfolk Island' by TE Robinson. Reproduced from Wilson and Davies (1980). Right, modified from Standerdmolen tekening postmill diagram by Rasbak, Wikimedia Commons.

The top weatherboard structure of the mill, containing the grinding equipment, rotated on a large central post, stabilised by eight stays. The mill contained the machinery to run a single pair of millstones and it was equipped with a dressing machine A.[10]

In 1844, concerns were raised about the stability of this post mill. As a result, a stone base was constructed around the lower supporting post and its stays in about 1849. The weatherboard building then was further supported by rollers that ran around the top of the stone base.

This windmill remained in place until it was destroyed by fire after the closure of the Second Settlement. The stone base of this windmill can still be seen on Point Hunter.[10]

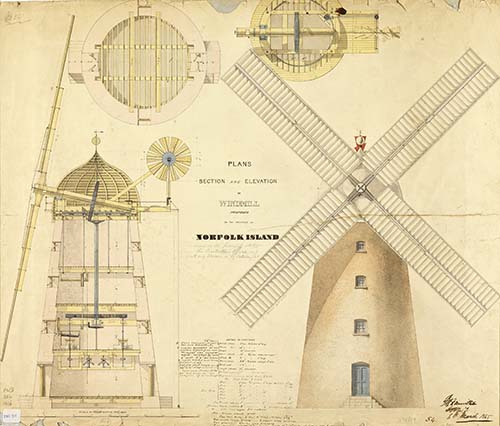

In 1845 it was proposed to build a much more advanced windmill on Point Hunter. Detailed plans for this proposed mill (see below) were preserved in the Archives of the State Library of Tasmania. However, this mill was never constructed.

Above, an 1845 plan for an elaborate windmill, proposed to be built on Point Hunter but never constructed. Plans, section and elevation, by RG Hamilton. Tasmanian Archives, State Library of Tasmania.

A: Dressing machine. A machine in a flour mill that purified the flour using sieves.

Millstones used in the Second Settlement

Numerous millstones would have been used in these many Second Settlement mills. Unfortunately, we have not yet found any documentation recording the source of these millstones. However, we suggest that they were probably quarried from the local Calcarenite Limestone, as they were in the First Settlement.

Calcarenite had been proven during the First Settlement to make effective millstones. These millstones could have been manufactured and supplied to the Second Settlement mills, free of charge, because:

– There was an abundant supply of Calcarenite Limestone on the island; and

– There were hundreds of unpaid convicts on the island who could be set to work quarrying millstones from this material.

It is unlikely that the authorities would have gone to the considerable difficulty and expense of importing higher quality millstones (such as French Burr Stones) from overseas, or even from Sydney, simply to feed this twice-convicted convict population.

Closure of the Second Settlement

In contrast to the First Settlement, the buildings of the Second Settlement were retained intact when the settlement closed in 1855.

The British Government planned to re-settle a group of Pitcairn Islanders onto Norfolk Island, and the buildings were kept for their use.

REFERENCES

1. Nobbs, Raymond (ed) (1991) Norfolk Island and its second settlement 1825-1855. Library of Australian History, page 104.

2. Wilson, Graham and Davies, Martin (1980) Norfolk Island : archaeological survey Kingston – Arthur's Vale region. Department of Housing and Construction, Australia, Vol 1, page 152.

3. Ibid, page 152.

4. Ibid, page 117.

5. Bunbury, T (1861) Reminiscences of a Veteran. Vol 2, page 295.

6. Wilson, Graham and Davies, Martin (1980) Norfolk Island : archaeological survey Kingston – Arthur's Vale region. Department of Housing and Construction, Australia, Vol 1, page 126.

7. Bunbury, T (1861) Reminiscences of a Veteran. Vol 2, page 296.

8. Nobbs, Raymond (ed) (1991) Norfolk Island and its second settlement 1825-1855. Library of Australian History, page 119.

9. Duncan B, Gibbs M, Richards L, Blucher J and Blake N (2014) Norfolk Island archaeological remote sensing survey report 2014.

10. Wilson, Graham and Davies, Martin (1980) Norfolk Island : archaeological survey Kingston – Arthur's Vale region. Department of Housing and Construction, Australia, Vol 1, page 144.

Read More About Norfolk Island's Flour Mills

•• Overview •• First Settlement Flour Mills •• Second Settlement Flour Mills •• Nathaniel Lucas •• Robert Nash •• Norfolk Island Millstones ••