Millstone Types: Basalt-like Cullin Stones

A fine-grained volcanic rock from Germany

AKA Lava Stone, Blues, Dutch Blues, Blacks, Cologne, Cullen Stones, Rhine Stones, Holland Stones.

Singleton Mills homepage > Overview of Stone types used for Millstones > Basalt-like Cullen Stones

Highly-regarded German millstones

The basalt-like lava stone used to make Cullin or Cullen millstones came from the Eifel Mountains area of western Germany. This hard basalt-like stone is very fine-grained and is dark blue-grey in colour. Technically this stone type is called 'tephritic phonolite'.[1, 2]

Above, a commemorative Cullin millstone from Andernach, Germany. This millstone was presented to the people of Farnham, Surrey, UK, in 1992, by the residents of Andernach, to mark the twinning of the two towns. Photograph by Mertbiol in 2022. Wikimedia Commons.

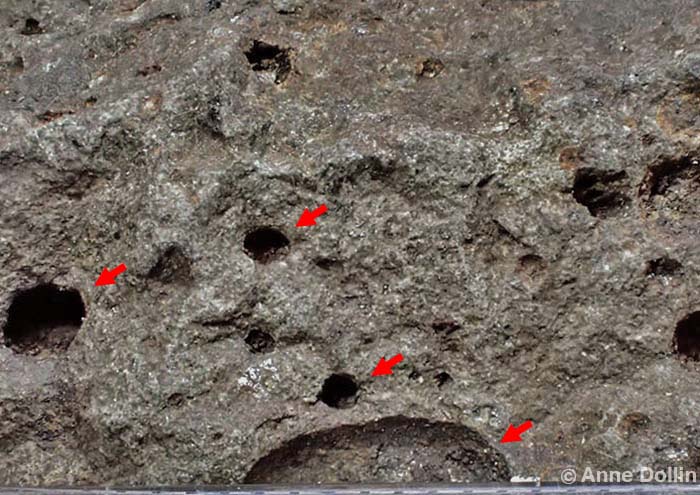

The lava stone, that was quarried for milling, was dotted with tiny holes, formed by gas bubbles trapped in the molten rock as the stone cooled – as seen in the photographs above and below. This texture is called 'vesicular'. The sharp edges of these tiny holes helped greatly improve the stone's grinding quality. Due to the excellent milling properties of Cullin millstones, their imports into the United Kingdom in the 1700s increased, and use of the British Millstone Grit Stones declined.[3]

Above, detail of the dark, fine-grained rock, featuring holes (see red arrows) produced by trapped gas bubbles, in a piece of Vesicular Basalt from the Blue Mountains area, NSW. The full width of this image shows a 20mm-wide section of the stone. Macro image by Anne Dollin.

Cullin Stone quarrying and export

The millstone quarries in the Eifel region of Germany were located near the communities of Mayen, Mendig, Kottenheim, Gerolstein, and Daun.[4] This area had produced millstones since Roman times. The stones were transported to Andernach (possibly carried by boat on the river Nette[5]), then were shipped down the Rhine to Cologne, and thence to England. The name 'Cullin' stone is a corruption of the town name, 'Cologne', through which the stones were shipped.

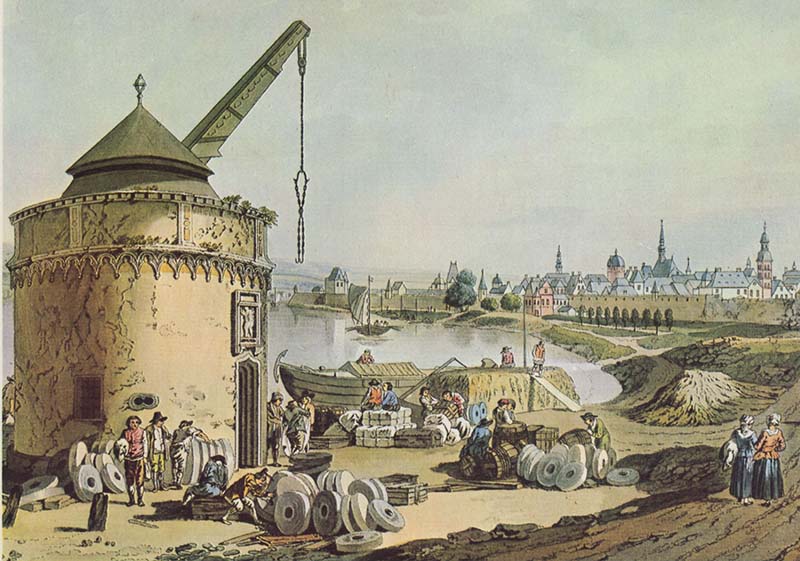

Above, an exquisite 1792 engraving of the old treadmill crane at Andernach, Germany, on the banks of the Rhine, with stacks of Cullen millstones awaiting transfer to their shipping vessels. Based on a watercolour painting by Laurenz Janscha; engraved by Johann Ziegler. Wikimedia Commons.

At Andernach, on the bank of the Rhine, an immense four-man treadwheel crane lifted and lowered millstones from vessel to vessel. It was in operation for 350 years, from 1561 to 1911, and it replaced an even-earlier wooden floating treadwheel crane. This historic crane still survives and can be seen in its original location at Andernach – see photograph below.

Above, the very historic treadmill crane at Andernach in Germany, still beautifully preserved in 2020. This crane was once used to transfer Cullin millstones onto boats to be shipped down the Rhine. Photograph by Wikhnsj, Wikimedia Commons.

Superseded in UK by French Burr Stones

The German Cullin or Cullen millstones were considered to be so much better quality than British millstones (such as Millstone Grit and Old Red Sandstone), that they were imported into Britain for flour milling from as early as the medieval period. Their main drawback was that dark dust from the Cullin millstones discoloured the milled flour. Then in the 1700s and 1800s, French Burr Stones, that could mill pure white flour, gained popularity in Britain,[6, 7] and these became more widely used than the Cullin stones.

REFERENCES

1. Shaffrey, Ruth (2021) Supplementary material in Feeding Roman Silchester: Querns and Millstones in and around Roman Towns. Britannica, Vol 52, Cambridge University Press.

2. Wenzel, Stefan, (2020) Lava rotary querns of 'Iron Age Type' in Roman times. Journal of Lithic Studies, 7(3): 1-40.

3. Polak, JP (1987) The production and distribution of Peak millstones from the sixteenth to the eighteenth centuries. Derbyshire Archaeological Journal, 107: 55-72.

4. Hockensmith, Charles D (1993) European millstone quarries: a bibliography. International Molinology, 49:30-32.

5. Wenzel, Stefan (2020) Transport of heavy loads on inland waterways. In: Herdick M, Hunold A and Schaaff H (Eds), Pre-modern Industrial Districts, Panel 3.12, Archaeology and Economy in the Ancient World 14 (Heidelberg, Propylaeum 2020), 53–65.

6. Polak, JP (1987) The production and distribution of Peak millstones from the sixteenth to the eighteenth centuries. Derbyshire Archaeological Journal, 107: 55-72.

7. Jobey, George (1986) Millstones and millstone quarries in Northumberland. Archaeologia Aeliana, 5(XIV): 49-80, page 51.

Read More About Millstones

•• Overview •• French Burr Stones •••• Millstone Grit •• Old Red Sandstone, Puddingstone, and Lodswoth Stone •• Granite •• Limestone •• Artificial Millstones •• Norfolk Island Millstones •• Colonial Millstones ••