How Steam-powered Mills Work

Singleton Mills homepage > Different types of mills > How steam-powered mills work

By the 1830s, steam-powered flour mills began to be constructed in regional New South Wales.

Instead of using wind or flowing water as the power source, these mills were powered by a steam engine fed by a boiler.

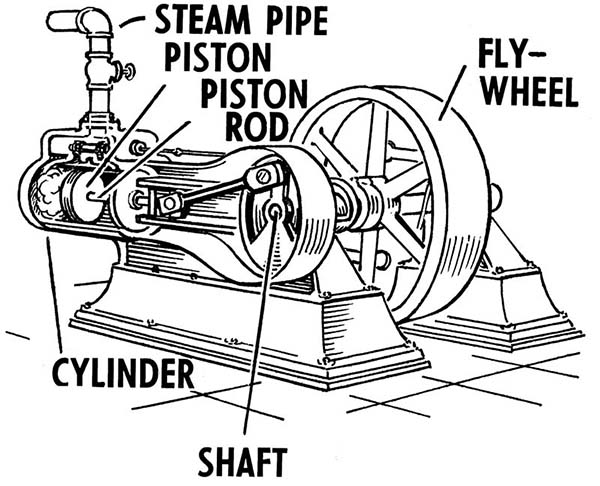

Above: a diagram of a steam engine. Source: Pearson Scott Foresman, Wikimidia Commons.

Steam engines were expensive but powerful, and these steam-powered mills did not need to rely on good winds or full creeks, as windmills and watermills did.

Multiple pairs of millstones could be driven by a steam engine and this allowed much larger mills to be constructed.

To meet the increasing demand for purer and whiter grades of flour, other machines were also added to later steam mills. These machines were powered by belt drives connected to the steam engine too. These machines included:

-- separators,

-- smutters,

-- brushing machines,

-- scalpers

-- purifiers, and

-- specialised flour roller mills.

The Singleton Family established three steam-powered flour mills in the township of Singleton between 1838 and 1860.

***** Further information to come *****

Further Reading

• Types of mills • How Tide and Water Mills Work • The Kurrajong Mills • The Wisemans Ferry Mills • Mills at Singleton